Peristaltik Dozaj Pompası

Peristaltik Dozaj Pompası

Peristaltik Dozaj Pompası Sistemi

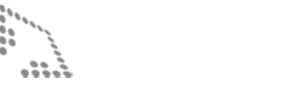

Bilgisayar Kontrollü Peristaltik Pompa Sistemi

Dijital Dozaj Pompası

İçindekiler;

Pompa Cihazı Programı, Yazılım, Adaptör

USB Kablosu, Konnektörler, Ücretsiz Kurulum Desteği

Ölçüler: Uzunluk 17 cm Genişlik 19 cm Yükseklik 14 cm

Peristaltik Dozaj Pompası Analog Pompa Cihazının

İçindekiler;

Pompa Cihazı, Adaptör, USB Kablosu, Konnektörler, Ücretsiz Kurulum Desteği

Ölçüler: Uzunluk 23 cm Genişlik 19 cm Yükseklik 14 cm

Dijital Pompa Teknik Özellikleri

Sistem hem gazlarda hem de sıvılarda çalışır.

Dozlama hassasiyeti 0,1 ml/dk'dır.

Minimum Dozlama 0,22 ml/dak.

Maksimum Dozlama 21,7 ml/dak.

Minimum Çalışma Sıcaklığı -10 °C

Maksimum Çalışma Sıcaklığı +60°C

220 V ile çalışır.

USB ile haberleşir.

Analog Pompa Teknik Özellikleri

Sistem hem gazlarda hem de sıvılarda çalışır.

Dozlama manuel olarak sınırlandırılır.

220 V ile çalışır.

Açma-kapama anahtarı ve sinyal lambası bulunmaktadır.

Maksimum Dozlama 1 litre/dak.

UYGULAMA ALANLARI

Boğaziçi Üniversitesi - Çevre Bilimleri Enstitüsü

Fırında ince film kaplama.

Seramik kaplama.

Kullanılan bağlantı parçaları dayanıklıdır.

Peristaltik Pompa Nedir?

Peristaltik pompalar peristalsis sistemi ile çalışan ve hortum boyunca hareket eden bir tıkanıklık ile sıvı basınçlarında volümetrik pompalardır. Üzerinde 2 veya daha fazla silindirin veya pedin döndüğü bir rotor, esnek bir elastik hortum ve bir elektrik motorundan oluşur. Peristaltik pompaların en büyük avantajı sıvının tamamen kapalı bir boru sistemidir. Bu nedenle sıvı pompanın kendisiyle temas kurmaz ve kullanımdan sonra tüp temizlenebilir ve sterilize edilebilir.

İlk rulo sıkıştırma ile hortuma doğru yuvarlanır. Bu, sıvıyı emen ve kapasiteli bir vakum oluşturur. Sıvı çıkışa ulaştığında, ikinci silindir işlemi yeniden başlatılır.

Hortum, pompanın sıvıyla temas eden tek parçası ve bu nedenle sıvıyla kimyasal olarak uyumlu ve ayrıca sıkıştırma ve sıkıştırma hareketine mekanik olarak dayanıklı olmalıdır. Hortumun ana özelliği, hortumun deforme olması ve orijinal şekline dönmesine izin verenin eklenmesidir, çünkü uzun ömürlü olmasını sağlar ve emme kapasitesi yeniden oluşturulur. Hortumun ana özelliği, hortumun deforme olması ve orijinal şekline dönmesine izin verenin eklenmesidir, çünkü uzun ömürlü olmasını sağlar ve emme kapasitesi yeniden oluşturulur. Hortum genellikle silikon ve/veya PVC ile yapılır.

Silindirler, sıvıyı baskılayan mekanik elemanlardır. Akış değişiminin artması, pompalanan sıvının seçimlerini ve mevcut durumlarını en üst düzeyde çıkarmak için 2 veya daha fazlası mevcuttur.

Peristaltik pompalar, sıvının pompa ile temas etmesi gereken işlemlerde (kirlenmemesi gereken tehlikeli sıvılar vb.) veya yüksek viskoziteli sıvıların veya çok sayıda askıda katı temizleme uygulamalarında kullanılır. Bu tip pompa, akış hızının sıcaklığının sürdürülmesi, onu dozlama işlemleri için uygun hale getirir, çünkü RPM miktarını seçmek için kapasite motorları uygulanabilir.

Peristaltik pompa, birçok amaç için kullanılan, kullanımı kolay bir cihazdır.

Avantajlar;

İçeriğindeki Emişli,

Askıda katı maddelerce zengin viskoz akışkanlar için uygundur,

Dozlamaya uygundur,

Sorunsuz kuru çalışma.

Polimer kalın film üretimi için sıvıları ölçer ve aktarır.

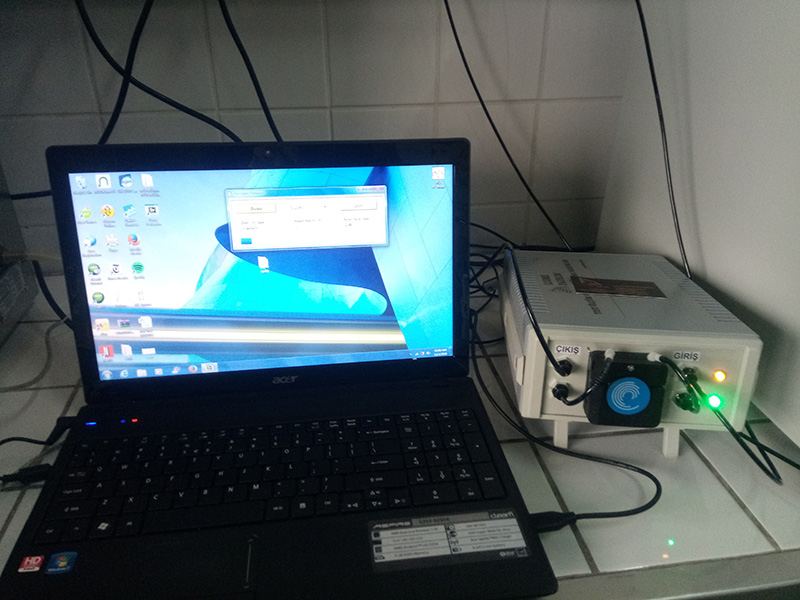

Peristaltik Dozaj Pompası Analog Pompa Cihazı

Peristaltik Dozaj Pompası Analog Pompa Cihazı

İçindekiler;

Pompa Cihazı, Adaptör, USB Kablo, Konektörler, Ücretsiz Kurulum Desteği

Boyutlar: Uzunluk 23 cm Genişlik 19 cm Yükseklik 14 cm