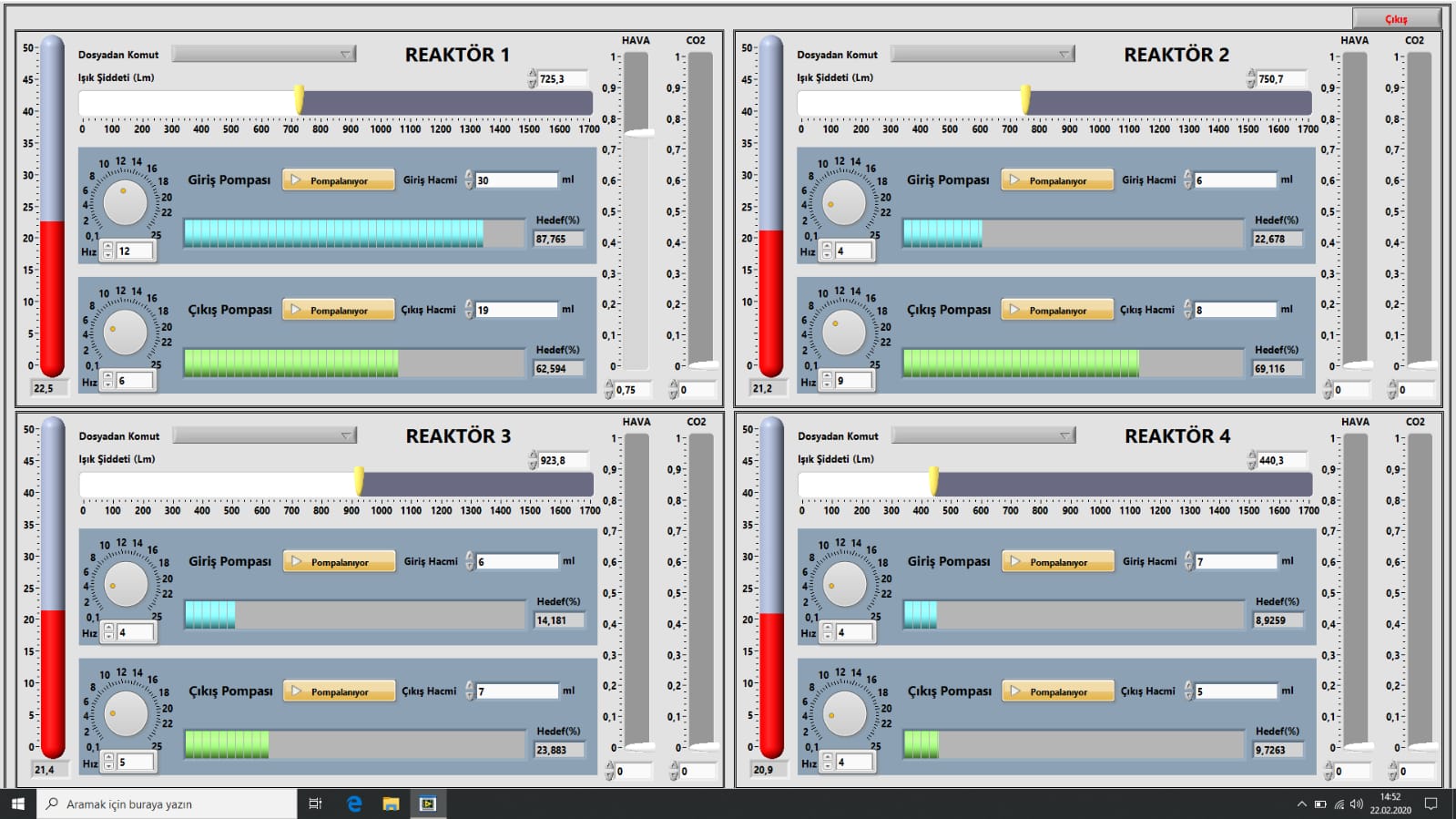

Biyoreaktör Kontrol Takip Sistemi

Biyoreaktör Kontrol ve Takip Sistemi

Alg Yetiştirme Sistemi

İçindekiler;

Karbon Dioksit Temini (CO2),

Hava Temini ve Kontrolü,

Numune Alma ve Besleme,

Peristaltik Sıvı Dozajlama,

Hassas Işık Şiddeti Kontrolü,

Bilgisayarlı Kontrol,

Pnömatik Devreler,

Sıcaklık Ölçümü ve Kontrolü,

Zaman Bazlı Senaryo Oluşturma,

Biyoreaktör Yazılımı,

Uzunluk 36 cm, Genişlik 36 cm, Yükseklik 15 cm

HAKKINDA

İç Sular Biyolojisi, Su Bilimleri, Alg Yetiştirme Biyoreaktör Sistemleri, Müşteriye özel tasarlanır ve buna göre imal edilir, istenilen özelliklere sahip olabilir.

Örnek bir senaryo yazmak için;

1. Sistemin kurulumu sırasında reaktörlere girecek peristaltik pompalar ve ışık-sıcaklık sensörleri firmamız tarafından reaktörlere entegre edilecektir.

2. Satın alınacak reaktörlere gaz çevrim sisteminin entegrasyonu tarafımızca sağlanacaktır.

3. Gaz döngüsü, her bir reaktör için tüm ekipmanı kapsayacaktır.

4. Her reaktörde kullanılacak farklı gaz türlerinin birleştirilmesi için gerekli donanım sağlanacaktır.

5. Reaktörlerin atık gazlarının toplanması ve taşınması için gerekli ekipmanlar tarafımızca sağlanacaktır.

6. Gaz ve sıvı giriş çıkışlarında hassas debi ayarı yapılabilecektir. Sabit akış olarak ayarlanabilir.

7. Tüm gaz dönüştürme aparatları karbondioksit ile çalışabilecektir. Aside dayanıklı malzemeden yapılacaktır.

8. Her bir reaktördeki sıcaklık bilgisayar kontrolü ile okunabilecektir.

9. Tüm sıcaklık sensörleri izole edilecek ve ıslak ortamlarda çalışabilecektir.

10. Sistem firmamız garantilidir.

13. Bilgisayar laboratuvar ortamında ergonomik kullanıma uygun olarak taşınabilir olacaktır.

14. Dizüstü bilgisayar istenen işletim sistemine sahip olacaktır.

15. Sistemdeki her reaktörde aydınlatma olacaktır. Bu aydınlatmalar hem bilgisayar kontrollü hem de manuel olarak ayarlanabilecek.

16. Aydınlatma rengi seçilebilir.

17. Her reaktör için ışık yoğunluğu yazılım aracılığıyla ayarlanabilir.

18. Her reaktörde peristaltik pompa bulunacak ve pompa hem manuel hem de bilgisayar kontrollü olarak çalıştırılabilecektir.

19. Pompalar çift yönlü çalışabilecektir. Reaktörlerden numune almak veya besleme eklemek için kullanılabilir.

20. Reaktörde kullanılacak veya ileride kullanılacak tüm yazılımlar destek süresi boyunca sisteme eklenecektir.

21. Yazılım; Sıcaklık, ışık şiddeti ve pompalanan sıvı miktarı gibi değişkenleri zamana bağlı olarak ölçülecek ve kontrol edilecek şekilde kaydedecektir.

22. Işık şiddeti ve pompa kontrolleri zamana bağlı senaryolar oluşturacaktır.

Biyoreaktör Nedir?

Mikroorganizmalar, bakteriler, mantarlar, maya, küf, algler, siyanobakteriler vb. Biyolojik materyal içeren bir kaptır. Bu ciltte cereyan eden olaylar belli parametreler dahilinde izlenmektedir. Çeşitli laboratuvarlarda yapılan araştırmalar sonucunda elde edilen veriler kayıt altına alınmaktadır.