TEST SİSTEMLERİ

Solid Waste Reactor Measurement System

Shale Gas Measurement - Research System

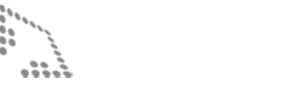

What is Shale Gas?

Shale gas or shale gas is found in the small pores of sedimentary rock composed of organic matter-rich clay and quartz and calcite minerals. It is an alternative gas to natural gas, which is among the unconventional energy sources, which can be transported to the earth by horizontal drilling and hydraulic fracturing methods.

Shale Gas Extraction Scheme

Not all shale rocks may contain shale gas, because they must contain a certain amount of organic matter and reach sufficient maturity. While oil and natural gas leave the main rock and settle in different rocks, shale gas is the gas that does not leave this main rock and remains.

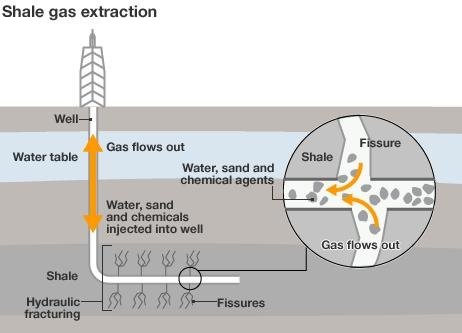

Shale Gas Basin of Some Countries

The following factors are very important in determining the shale gas potential:

Total Organic Carbon (TOC) amount in rocks,

Presence of high pressure in the rock,

Stress distribution profile in the rock.

Proportions of minerals such as clay, quartz and calcite in rocks,

The rocks are deep enough,

The organic matter in the rocks has reached maturity to form gas.

Permeability and adsorption in bedrock are the two main mechanisms controlling the deposition of shale gas. It is very important to examine these two elements in the samples taken.

.jpg)

Our company provides test-measurement services in Shale gas research.

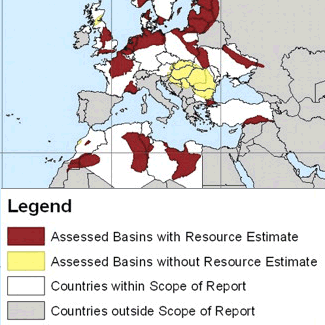

Algae (Cultivation/Cultivation) Reactor - Algal Biodiesel and Biofuel

Although biodiesel and biofuels have almost the same energy level as other solid fuels, they release less into the atmosphere. Since biodiesel and biofuels release less into the atmosphere (due to environmental reasons), it is a serious issue as a fuel. Biodiesel and biofuels are currently produced from many agricultural products by various processes. However, the issue of obtaining biofuel from algae has come to the fore in time. This is because algae can produce energy through photosynthesis. Algae store their products as oil, not starch. The oil obtained from algae can be used directly as fuel in diesel engines and can also be converted into biofuel by purification. Moreover, much more efficient production can be made from the oil obtained from agricultural products. One of the reasons why algae are preferred is that they grow rapidly and are not easily affected by environmental conditions. One of the reasons why it is preferred is that CO2 and waste water can be given to algae as food. This means that energy can be produced in an environmentally friendly way. In this sense, many studies on algae continue. Our company actively provides services in the fields of reactor design-manufacturing and reactor monitoring systems in these studies.

Reactor Design and Tracking Systems

Reactor: These are structures that are used to simulate and observe various events and to examine the working efficiency and properties of these events under different conditions. The reactors vary in material, reaction and reaction conditions under investigation. Our company designs and manufactures reactors according to the desired specifications.

Reactor Tracking Systems:

Temperature Monitoring and Control,

pH Monitoring and Control,

Dissolved O2 Monitoring and Control,

Conductivity Monitoring and Control,

CO2 Monitoring and Control,

Pressure Monitoring and Control.

The reactor is monitored and controlled by the computer, and the change of each data against time is recorded and displayed graphically on the screen. There are critical set values required for many reactions (for the reactions to take place properly). This set value is defined to the computer and is one of the values set with the PID control mechanism. In case of deviations, it automatically intervenes in the system and ensures that it reaches the set value. The most common examples of these set values are; temperature, pH and Dissolved O2.

MFC (Mikrobial Fuel Cell)

Microbial fuel cells are systems that use microorganisms as catalysts in an oxygen-free environment and directly convert the chemical energy formed as a result of the oxidation of organic substances into electrical energy.

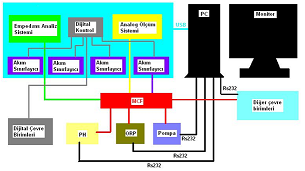

An Automation Scheme That Can be Applied to MFC (Microbial Fuel Cell)

Various MFC Reactor Design Types

An MFC reactor model designed by our esteemed teacher 'Barış ÇALLI' in the studies carried out at 'Marmara University'.

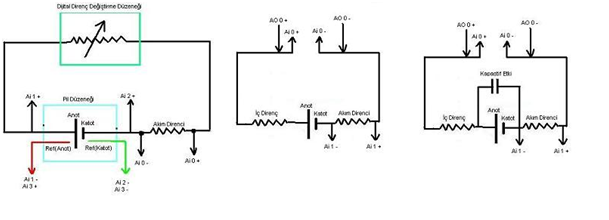

Possible Measurements;

Monitoring and recording the current,

Monitoring and recording of current density, external power and external energy values,

Online measurement of internal resistance,

Internal power and energy losses measurement (Efficiency),

Possibility of measurement at constant current and constant battery potential,

Cronopotentiometry measurement,

Cronoampermetry measurement,

DC impedance measurement,

AC impedance measurement,

Lissajous impedance measurement,

Nyquist impedance measurement,

MFC (Microbial Fuel Cell) Energy Store,

Impedance Analysis System,

Computer Based Impedance Analysis Systems for Solid and Ionic Media.

Our Application Examples;

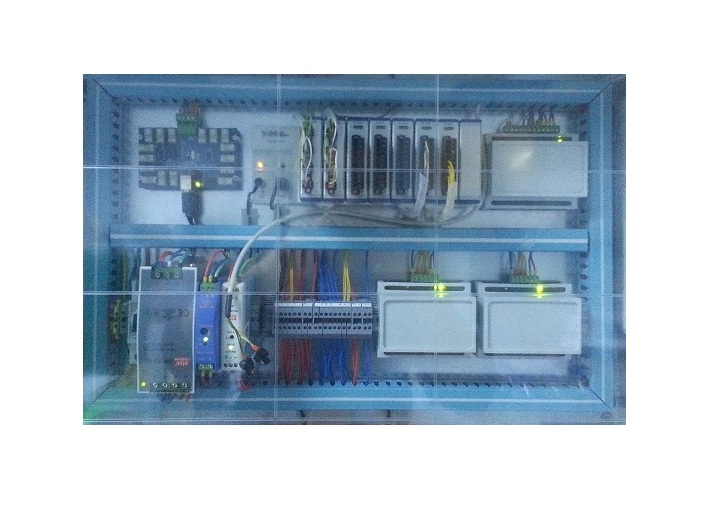

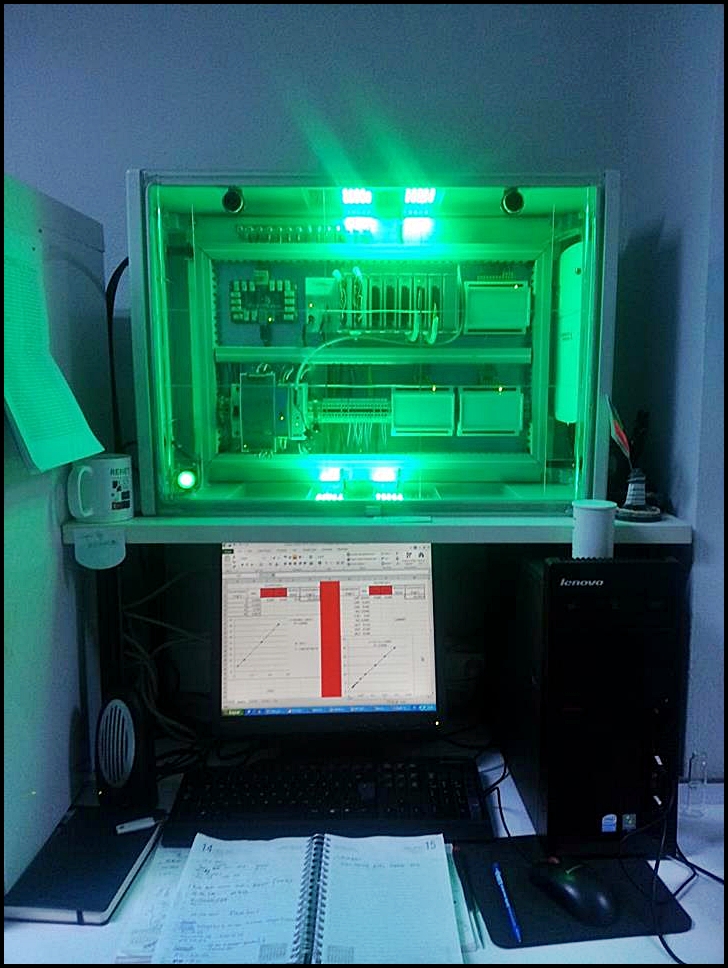

Computer Aided Temperature Control System MFC Control and Analysis System.

.jpg)

.jpg)

Impedance Analysis System

Computer Based Impedance Analysis Systems for Solid and Ionic Media.

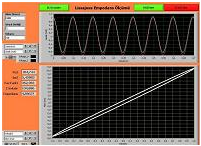

Lissajous Impedance Analysis System

Creation of a lissajous impedance graph based on frequency and current conditions. Calculation of real and imaginary impedance vectors.

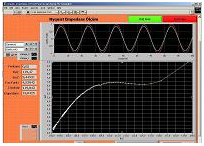

Nyquist Impedance Analysis System Obtaining the nyquist impedance plot in the desired amplitude and frequency range and calculating the real impedance value at the DC limit.

Frequency range options; 40 hz - 0.05 hz 1 khz - 1 hz 10 khz - 1 hz10 Mhz - 1 hz

Liquid Nitrogen (Nitrogen) Cooling and Measurement System

Small samples can be cooled down to -150 degrees. Desired temperatures are in the form of constant or time-dependent functions. The temperature control is controlled by the computer with the PID algorithm. The heat exchange is variable according to the sample type and dimensions. It creates a more linear heat distribution than liquid phase pumping.

.png)

Heating Cooling Systems The system or sample is brought to the desired temperature with the PID algorithm. Functional heat values, ramping, measurement possibilities according to the desired and generated heat are controlled by the computer. Temperature measurement techniques; Thermocouple, pt100, pt1000, thermistor and non-contact sensors. Heating techniques; It would be water, hot air, electromagnetic induction, light. Cooling techniques; Gas cooling systems, peltier, liquid nitrogen (nitrogen), liquid nitrogen vapor.

Research Reactor Design

Material Selection; Stainless steel, plexiglass, glass, teflon. Technique: Laser and CNC cutting

Pressure Stabilization System

Inlet pressure 0 m.Bar.

The highest outlet pressure is 2 Bar.

O high gas flow 6 liters/hour.

Carbon Dioxide Washing System

.png)

The inlet gas is passed through the acid-salt solution continuously in a closed loop. The 60 Watt peltier cooler cools the outlet gas.

Bubble forming hole diameter 0.6 mm.

The highest recommended gas flow rate is 10 liters/hour.

The coolant and gas circulation pump are driven by the computer according to the desired criteria or scenarios.

Reactor Tracking System

It has the features of gas measurement in research reactors and CO washing and water vapor condensation of the produced gas. The pressure on the reactor can be fixed at 0 m.Bar or adjusted between +-10 m.Bar. Sample tracking is followed by the computer and included in the calculations. The feeding is done automatically by the computer by connecting to certain criteria and scenarios.

Water Vapor Condensation System

The gas inlet is cooled by a 96 Watt pertier cooler as it passes through the chamber whose surface is enlarged with steel, glass or stainless steel.

The condensed water vapor settles under the silicone oil in the second chamber. The highest recommended gas flow rate is 6 liters/hour. Peltier is driven by computer based on gas flow rate or other criteria.

Electronic Waste Sample Preparation

The preparation of samples to be studied in Electronic Waste Recycling Projects, especially in Environmental Engineering departments, is as important as the execution of the studies. Our company prepares electronic waste samples for electronic recycling projects with the experience gained in the field of R&D.

Jet Engine Control and Working Set

Turnkey full computer controlled jet engine control and measurement system.

Jet Engine Work Set Content and Features;

Jet Engine, Engine Protection Unit, Turbine Mounting Clamp, Control Module, Fuel Tank and Fuel (Kerosene), Miniature Fuel Pump, Fuel Control Electronics, Electronic Start Gas Valve, Electronic Fuel Valve, Starting Gas Tank, Fuel Pipe, Pipe Connector Kit, Filters and Wiring Kit, Battery (with required specs), Input / Output LED Board, Data Acquisition System.

Data Acquisition and Control Software (can work with desktop or laptop)

Measurements Made;

Engine Exhaust Temperature,

Engine Outlet Temperature,

Vibration,

Microphone (revolution reading with sound analysis),

Engine speed etc.