TEST SİSTEMLERİ

Ultrasonic Measurement System

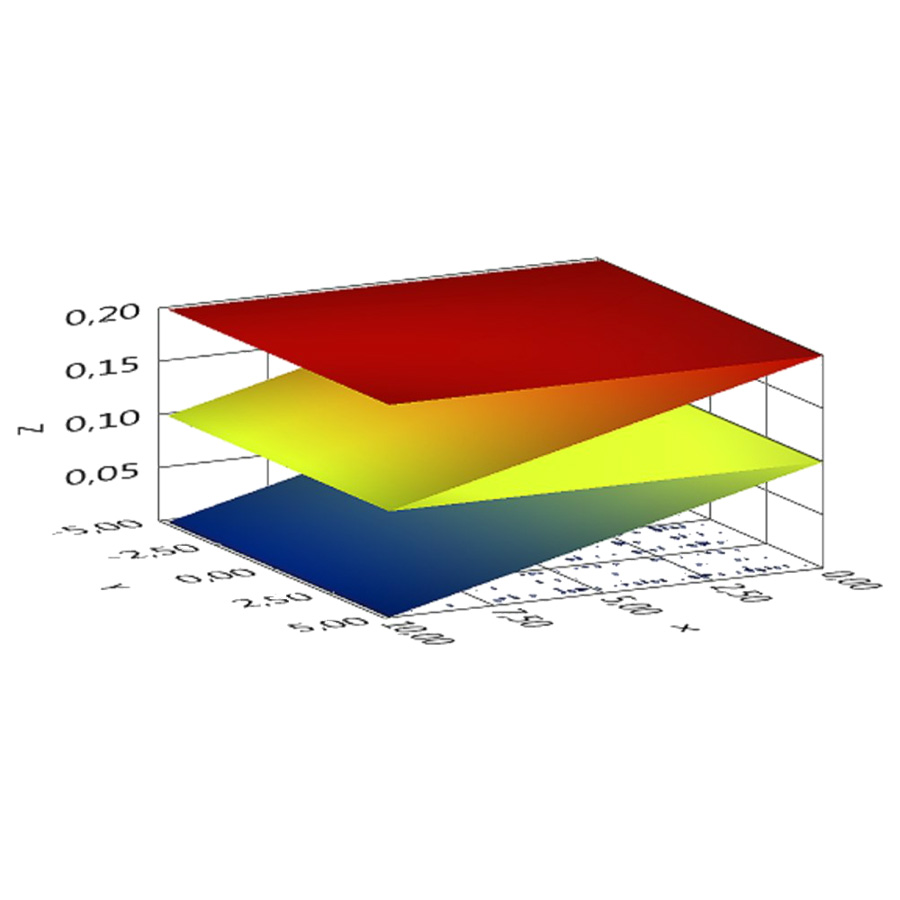

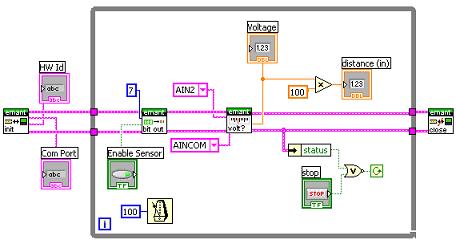

Ultrasonic measurement system connected to the coordinate with the motion control system in the water.

Possible Measurements;

- Linear, surface or 3D space scanning,

Computer-based ultrasonic inspection techniques have proven their reliability today and are widely used in the industry. If we categorize it briefly;

Pulse – Echo Ultrasonic Inspection

It is based on the principle that high-frequency sound waves are sent into the material to be checked and examined using its reflection and transmission properties. Ultrasonic wave is sent into the material by the generator (transducer). Reflected or transmitted waves are collected by the receiving transducer and transmitted to the ultrasonic inspection device. By analyzing the sound echo dynamics, a decision is made about whether the material is defective.

Phased Array Ultrasonic Inspection

Ultrasonic wave generator (transducer) consists of multiple sound generators that produce sound independently of each other. Ultrasonic waves with phase difference produced from these generators at different times are sent into the material by performing constructive and destructive interferences. The received waves are sent to the phase difference measuring device and the data is processed and visualized.

This inspection technique has many advantages over the traditional pulse-echo ultrasonic inspection technique. Phased Array ultrasonic waves have the features of electronically scanning, focusing and imaging at different angles.

The most important advantage; It is the ability to inspect complex geometries and thick materials.

- Liquid Temperature,

Traditionally, a thermocouple is used for the determination of the melting temperature. However, the fact that it is a contact measurement system and has a very slow response time causes these techniques to not provide reliable measurement results.

A non-contact temperature measurement system based on ultrasonic technology does not affect the material while making precise measurements. In addition, a homogeneous temperature and melt viscosity are provided.